Orifice Plate Assembly

Description

The Orifice Plate is a differential pressure device suitable to measure the flow rate in a closed conduit (it is an affordable device for general applications).

Main Reference code: ISO 5167/ASME MFC-3M; ASME PTC 19.5

As per Customer’s requirements / Main material Reference: ASTM-ASME Code

Type of Elements:

- Square Edge Orifice / Quadrant Orifice / Conical Entrance Orifice / Segmental orifice

Type of Pressure – Taps and Relevant Calculation:

- Flange Taps

- Corner Taps

- Radius Taps

- Pipe Taps

Type Of Construction:

- Flange Taps: with pressure taps on flanges or on carrier ring

- Corner Taps: with pressure taps on flanges, or on annular chambers, or on a monolithic late

- Radius / Pipe Taps: pressure taps shall be welded on pipe (in this case the assembly shall be supplied complete with the relevant spool pipe)

Type of Place Connections:

All / Main Connections: RF-RJ

Type of Flanges:

WN-SW-LJ-THD-SO according to International Standards (ANSI/ASME/UNI/DIN/API)

Other Options:

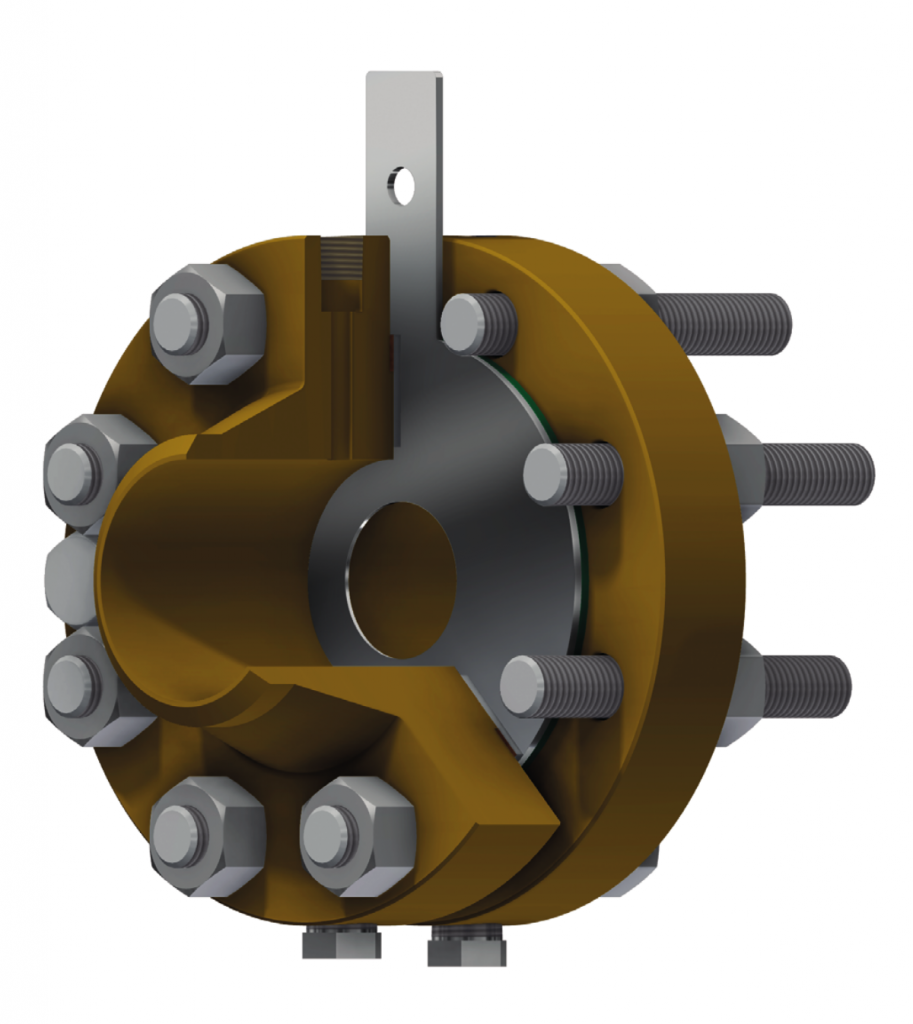

Single Chamber Orifice Plate Assembly: is a special kind of construction with a system that allows an easy removal of the plate from the assembly

Dual Chamber Orifice Plate Assembly: is a special kind of construction with a system that allows an easy removal of the plate from the assembly under pressure (with the line still in operation)

Calibration

Performances

- Accuracy (referred to the discharge coefficient): as per ISO Code

- Rangeability: 1÷4.5

- Repeatability: +/- 0.1%

- Max PPL 50÷70% of full scale differential pressure

- Straight Lengths Requirements: as per ISO 5167

Notes

- Flow Meters can be manufactured according to Customer specifications

- Flow Meter can be supplied complete with all relevant accessories (valves / manifold / condensing pot / transmitter / fitting / tubing)

TYPICAL SUPPLY CONFIGURATION:

Orifice Plate only

Orifice Plate Assembly

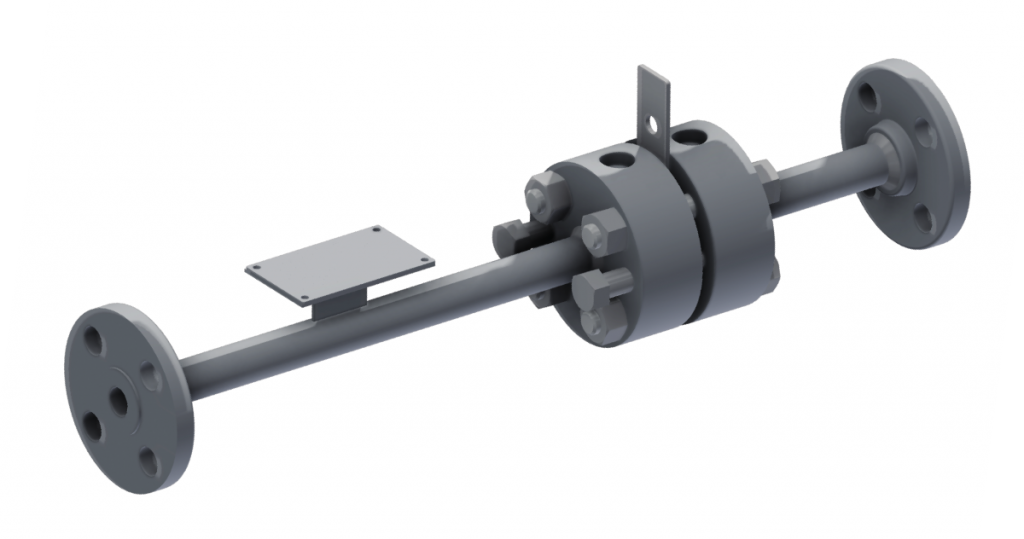

Meter Run Assembly (up to 2”)

Complete Upstream/ Downstream Spool Orifice Assembly (with Flow Conditioner, if required) for 2” and above